Steel plate welding, do you think it's just that simple to weld two steel plates together? If you think so, you are very wrong. Welding, also known as welding or welding, is a manufacturing process and technology for joining metals or other thermoplastic materials (such as plastics and steels) by heating, high temperature or high pressure. Its process is a process in which two or more of the same or different materials are connected through the combination and diffusion of atoms or molecules. The method of promoting the binding and diffusion between atoms and molecules is heating or pressing, or heating and pressing at the same time.

The earliest modern welding technology appeared at the end of the 19th century, first arc welding and oxygen gas welding, and later resistance welding. After a long period of accumulation and development, steel welding technology in our country has become more and more mature. With the rapid development of society and the rapid development of production and construction, the demand for steel plates is getting larger and larger, which has caused the market to exceed supply, and the prices of steel plates have continued to rise. This is a reminder to manufacturers on the market that it is even more difficult to process steel plates. Waste, we need to save every inch of material, and improve cost performance for customers.

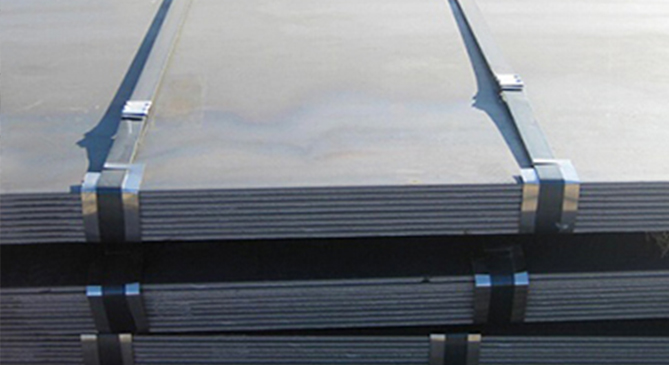

AHL STEEL, Steel Plate Manufacturer, as a professional steel plate distributor in Henan, will introduce some techniques for steel plate welding today. First, try to reduce the gap between the welding pieces as much as possible (the tighter the better). If you want to fill the welding wire, the welding wire must be thin, 0.8 is enough. The current should be smaller, so small that it can melt the welding wire, about 30A, the welding machine is different, depending on each welding machine

The welding speed must be fast, the faster the better, the smaller the deformation, the more beautiful the weld, and the better if there is water cooling. In addition, the welding machine is also particular about it. Generally, an inverter AC / DC welding machine is used, and the current is relatively stable. This welding opportunity is slightly more expensive. In fact, the use method is the same.

AHL STEEL has been engaged in sales and cutting of various steel plates for many years and has rich experience. If you need, please contact our online customer service. We believe: With your suggestions and help, we will do better.