The so-called numerical control cutting refers to the workpiece instruction (or program) used to control the machine tool or equipment, which is a new control method given in digital form. When the instructions are provided to the control device of the CNC automatic cutting machine, the cutting machine can automatically cut according to the given program.

The first is the method of

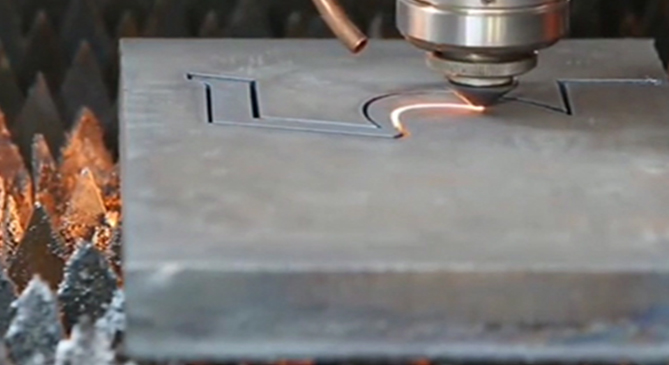

laser cutting steel plates. Cutting quality: excellent inclination and small area affected by heat. Basically no slag can achieve good to excellent fine cutting effect under the narrowest bending conditions. Production capacity: The cutting torch can be quickly disengaged, which improves the production efficiency. When cutting metal materials with a thickness of less than 6mm, the speed is extremely fast. The thicker the metal, the slower the speed, the thicker the metal, and the longer the perforation time. Generally, laser cutting is used in non-metal cutting metals. Only high-precision laser cutting is used!

The following is the method of plasma cutting steel plate: cutting quality: excellent inclination, small area affected by heat, almost no slag, good to excellent fine cutting effect. Production capacity: extremely fast speed and extremely fast perforation when cutting metal materials of various thicknesses

The last is the method of flame cutting steel plate: cutting quality: good inclination angle, large area affected by heat, large amount of slag, and need rework. Production capacity: slow cutting speed, preheating time will increase the number of perforations

AHL STEEL has many years of experience in sales and cutting of steel plates. If you need, please contact our online customer service, we believe: with your suggestions and help, we will do better.