The

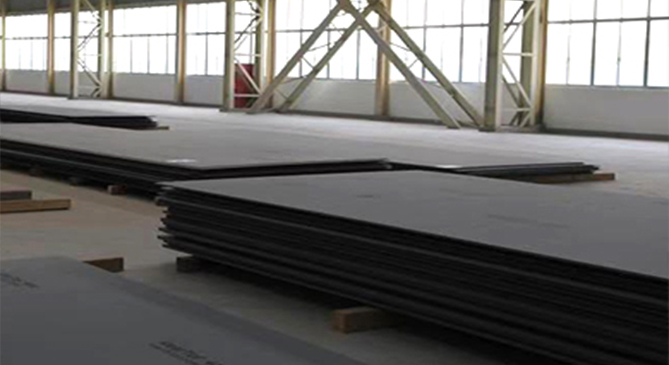

wear-resistant steel plate has high wear resistance and good impact performance. It can be cut, bent, welded, etc. It can be connected to other structures by welding, plug welding, bolting, etc., which saves time during the maintenance site process. And convenience, widely used in metallurgy, coal, cement, electricity, glass, mining, building materials, bricks and other industries. Compared with other materials, it has a high cost performance and has been favored by more and more industries and manufacturers. .

Next we look at the bucket of the power shovel excavator. This bucket is composed of the following main parts: The bucket consists of the bucket body (forearm, bucket back), bucket bottom, lifting beam, bucket teeth, pulley and balance wheel. In order to improve the service life of the bucket,

wear-resistant steel plates are widely used as materials for the main parts. The front and rear walls of the bucket are mostly connected with welded plungers between the front and rear walls of wear-resistant steel plates. The front wall is equipped with wear-resistant bucket teeth, which can be replaced after the bucket teeth are damaged. It is usually made of high-strength wear-resistant steel.

The lifting beam is made of high manganese steel into an I-shaped structure with reinforcing ribs. Ears are connected to the pulley and the bucket body. The bottom of the bucket can be welded with a wear-resistant steel plate on the bottom plate of the integral casting to increase the service life. The base plate can be made directly from wear-resistant steel plates. The bottom of the bucket adds abrasion-resistant strips to increase the strength. The bucket bolt and the bucket bolt are easy to wear parts, and it is best to use wear-resistant steel plates.

In order to improve the work of the bucket, the forearm of the bucket is slightly higher than the rear wall. In order to facilitate unloading and avoid large rocks blocking the bucket, its lower part is wider than the upper part. In order to prevent the lower part of the forearm from abrading and protruding forward, the bucket is welded with high strength and resistance Grinding plate to prevent bucket wear.

The above is some knowledge about buckets made of wear-resistant steel.

AHL STEEL operates weather-resistant steel, wear-resistant steel plate, marine steel plate, high-strength steel plate of various materials all year round. Welcome to contact us if necessary.